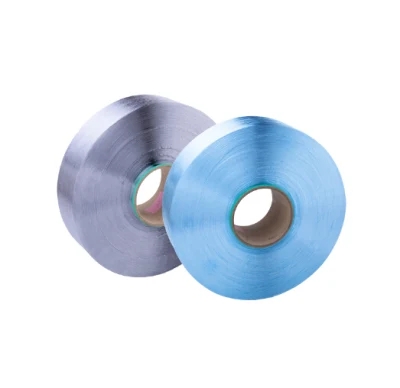

PP yarn means polypropylene yarn. It is a fiber obtained by polymerization and melt spinning from propylene as raw material. Polypropylene officially

started industrial production in 1957 and is a rising star in synthetic fibers. Because polypropylene has the advantages of simple production process,

cheap products, high strength and light relative density, polypropylene has developed rapidly. At present, polypropylene is the fourth largest variety

of synthetic fibers, and it is the lightest fiber among common chemical fibers.

Chemical properties

The scientific name is polypropylene fiber. It melts near the flame and is flammable. It burns slowly and emits black smoke. The upper end of the flame

is yellow and the lower end is blue.

Physical properties

1. Form The longitudinal surface of polypropylene fiber is straight and smooth, and the cross-section is circular.

2. The biggest advantage of density polypropylene is its light texture. Its density is only 0.91g/cm3, which is the lightest variety among common chemical

fibers. Therefore, polypropylene of the same weight can obtain a higher coverage area than other fibers.

3. Strong elongation Polypropylene has high strength, long elongation, high initial modulus and excellent elasticity. So polypropylene has good abrasion

resistance. In addition, the wet strength of polypropylene is basically equal to the dry strength, so it is an ideal material for making fishing nets and cables.

4. Light hygroscopicity and dyeing properties, good warmth retention; almost no moisture absorption, but strong wicking ability, obvious moisture

absorption and perspiration effect; polypropylene has very little hygroscopicity, almost no moisture absorption, and the moisture regain under general

atmospheric conditions is close to zero . But it has a wicking effect, passing water vapour through the capillaries in the fabric, but does not have any

absorption effect on its own. Polypropylene has poor dyeability and incomplete chromatogram, but it can be compensated by the method of dope dyeing.

5. Acid and alkali resistance Polypropylene has good chemical corrosion resistance. Except for concentrated nitric acid and concentrated caustic soda,

polypropylene has good resistance to acid and alkali, so it is suitable for use as filter material and packaging material.

6. Light fastness, etc. Polypropylene has poor light fastness, poor thermal stability, easy aging, and is not resistant to ironing. But the anti-aging performance

can be improved by adding anti-aging agent during spinning. In addition, polypropylene has good electrical insulation, but it is easy to generate static

electricity during processing. Due to the small thermal conductivity of polypropylene, the heat preservation is good.

7. High strength The strength of polypropylene elastic yarn is second only to nylon, but the price is only 1/3 of nylon; the fabric is stable in size, good in

wear resistance and elasticity, and has good chemical stability. However, it has poor thermal stability, is not resistant to sunlight, and is prone to aging

and brittle damage. For this reason, anti-aging agents are often added to polypropylene.

English

English Español

Español Português

Português Pусский

Pусский Français

Français Deutsch

Deutsch 日本語

日本語 한국어

한국어 Italiano

Italiano عربى

عربى